NEBUFAB | PHOENIX

The universal 3D printer

Print any filament material: PEEK, ULTEM, Metal...

Professional solutions to your most complex design and manufacturing problems, thanks to our expertise in additive manufacturing.

Talk to an expert

Professional 3D printer

Advantages

-

High temperature:

extruders 500°C, build chamber 230°C -

Multimaterials: polymers, composites, metals and more

-

Open, scalable software

-

2-year warranty with

service contract included

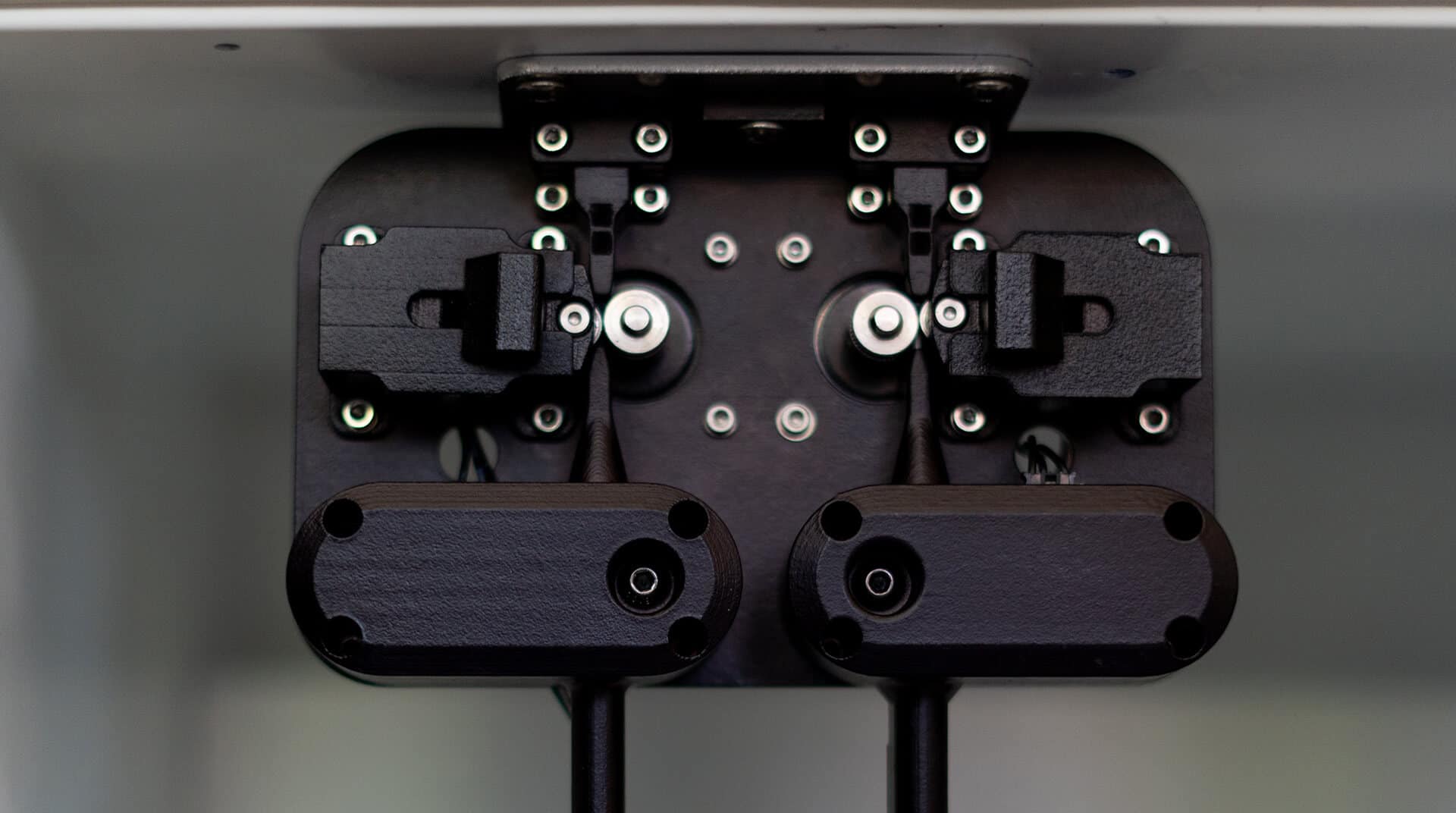

2 extruders at 500°C and 4 contact points

Allows printing on all types of filament

Open control system

Change parameters freely with the option of modifying the machine configuration

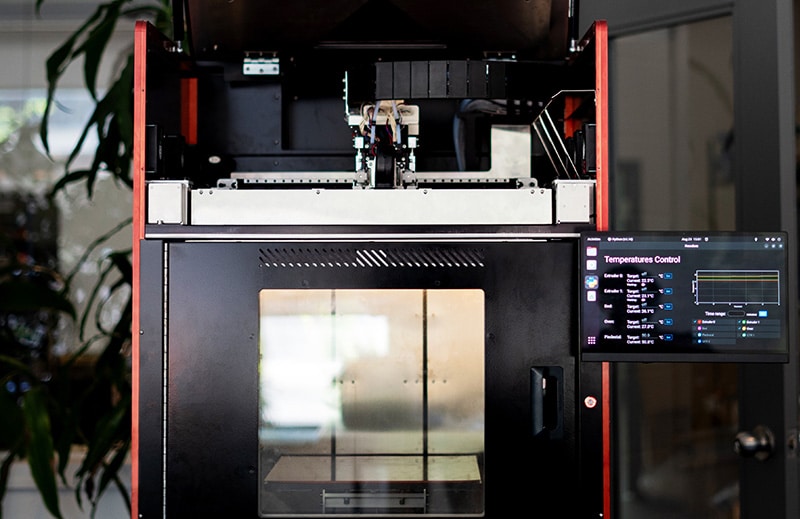

Print chamber isolated from mechanical components

Large build volume at 230°C

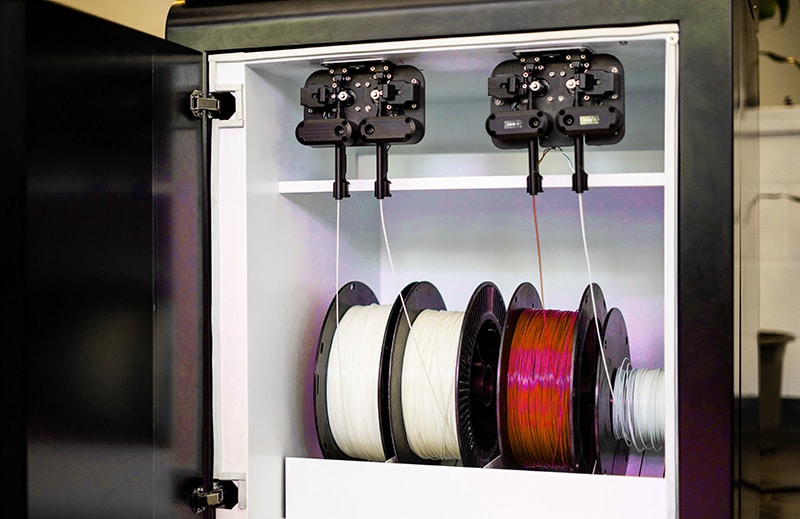

Humidity-controlled heated filament compartment

Automatic spool change

Robust, high-quality structure

For accurate, reproducible prints

Technical specifications

Nebufab Phoenix 3D printer

Print PEEK, ULTEM, Composites, Metal and more

-

Build chamber isolated from mechanical components

-

2 extruders at 500°C and 4 contact points

-

Open control system

-

Made and designed in Canada

High temperature printing

2500W heating chamber and heating plate

Don't wait hours to stabilize the temperature before printing!

The chamber’s powerful heating system, combined with an exclusive fan and heating plate, enables rapid, even heating up to 230°C, for reliable, high-quality printing with materials such as PEEK, PPSU or PEI.

Print any material

Extruders heated to 500°C with 4 contact points

Don't be limited in your choice of materials

Thanks to a 200W heater each with 4 motorized drive rollers, the extruders can extrude even the most filled filaments, such as PEEK-CF or metal or ceramic filaments, as well as filaments filled with nanoparticles.

Their easy-to-maintain design makes nozzle changing quick and easy.

Ventilation system with activated charcoal HEPA filter

The ventilation system has two functions:

- To cool the mechanical system and the external wall of the machine to keep everything at room temperature.

- Eliminate unpleasant odors and toxic particles associated with certain materials

Never run out of material when printing!

The feeding system manages two spools of wire per extruder, so you’ll never run out of filament during production. It is fully automated, with sensors monitoring the printing process.

Need a 3D printer?

Explore new horizons with innovative additive manufacturing techniques and expert advice.